Mastering Coupling Lubrication: A Complete Guide to Selection, Application, and Maintenance

Couplings are critical components in mechanical systems, serving as the connection between two rotating shafts to transmit power and accommodate misalignment.

Proper lubrication of couplings is essential to ensure their longevity, efficiency, and reliability. Without adequate lubrication, couplings are prone to wear, overheating, and eventual failure, which can lead to costly downtime and repairs.

This article delves into the intricacies of coupling lubrication, covering everything from lubricant selection and application methods to failure modes and monitoring practices.

The Role of Lubrication in Couplings

Couplings are subjected to a variety of stresses, including torque transmission, misalignment, and vibration.

These stresses generate friction and heat, which can lead to wear and damage if not properly managed. Lubrication plays a vital role in mitigating these effects by reducing friction, dissipating heat, and protecting against corrosion.

Additionally, lubricants help to seal out contaminants such as dirt, water, and other debris that can compromise the performance of the coupling.

The type of coupling in use—whether it is a gear coupling, grid coupling, or flexible coupling—determines the specific lubrication requirements.

For example, gear couplings rely heavily on lubrication to prevent metal-to-metal contact between the gear teeth, while flexible couplings may require less lubrication depending on their design. Regardless of the type, proper lubrication is a cornerstone of coupling maintenance.

Selecting the Right Lubricant for Couplings

Choosing the appropriate lubricant for a coupling is a critical step in ensuring optimal performance. The selection process involves considering several factors, including the type of coupling, operating conditions, and environmental factors.

Type of Coupling

Different types of couplings have unique lubrication requirements. Gear couplings, for instance, require a highviscosity lubricant with extreme pressure (EP) additives to handle the high loads and sliding motion between the gear teeth.

Grid couplings, on the other hand, may use grease or oil depending on the design and manufacturer recommendations.

Flexible couplings, such as elastomeric or disc couplings, may not require lubrication at all, as they rely on nonmetallic components to accommodate misalignment.

Operating Conditions

The operating conditions of the coupling, including speed, load, and temperature, play a significant role in lubricant selection.

High-speed couplings generate more heat, necessitating a lubricant with good thermal stability and low volatility.

High-load applications require lubricants with excellent film strength and EP additives to prevent wear. Temperature extremes, whether hot or cold, also influence the choice of lubricant.

For example, synthetic lubricants are often preferred in high-temperature environments due to their superior thermal stability.

Environmental Factors

Environmental conditions such as humidity, dust, and exposure to chemicals can impact the performance of the lubricant.

In wet or humid environments, a lubricant with good water resistance and corrosion protection is essential. In dusty or dirty environments, a grease with good sealing properties can help prevent contaminants from entering the coupling.

Compatibility

It is important to ensure that the selected lubricant is compatible with the materials used in the coupling, such as seals, gaskets, and elastomers.

Incompatible lubricants can cause swelling, hardening, or degradation of these materials, leading to leaks and other issues.

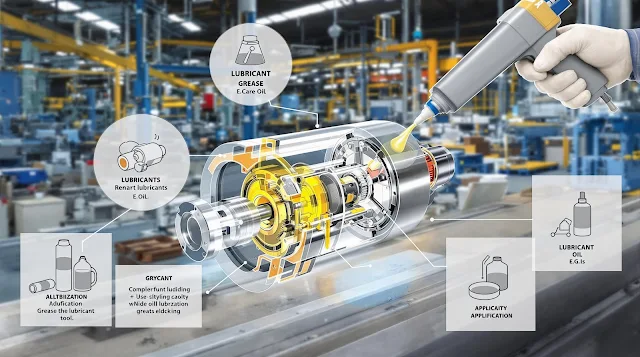

Application Methods for Coupling Lubricants

Applying lubricant correctly is just as crucial as choosing the appropriate type. Improper application can result in issues such as inadequate lubrication, contamination, or excessive lubrication, all of which can negatively impact the coupling's performance.

Initial Lubrication

When installing a new coupling, it is essential to apply the lubricant according to the manufacturer’s recommendations.

For gear couplings, this typically involves filling the coupling housing with the specified amount of lubricant to ensure complete coverage of the gear teeth.

For grid couplings, the grease should be evenly distributed across the grid and grooves to provide uniform lubrication.

Relubrication

Couplings require periodic relubrication to maintain their performance. The frequency of relubrication depends on factors such as the type of coupling, operating conditions, and the lubricant used.

For example, gear couplings in highspeed applications may require relubrication every few months, while those in lowspeed applications may only need it once a year.

It is important to follow the manufacturer’s guidelines for relubrication intervals and to use the same type of lubricant to avoid compatibility issues.

Application Techniques

The method of applying the lubricant can vary depending on the type of coupling and the lubricant used. For oillubricated couplings, a pump or oil can may be used to fill the housing.

For greaselubricated couplings, a grease gun is typically used to inject the grease into the coupling through designated fittings. It is important to avoid overlubrication, as this can lead to excessive heat generation and leakage.

Common Failure Modes Related to Coupling Lubrication

Improper lubrication is one of the leading causes of coupling failure. Understanding the common failure modes can help in diagnosing and preventing issues.

Insufficient Lubrication

Insufficient lubrication occurs when there is not enough lubricant to form a protective film between the moving parts of the coupling.

This can result from inadequate initial lubrication, infrequent relubrication, or lubricant leakage. Insufficient lubrication leads to increased friction, wear, and heat generation, ultimately causing premature failure of the coupling.

Contamination

Contaminants such as dirt, water, and chemicals can compromise the performance of the lubricant and the coupling.

Contamination can occur during the initial application, through leaks in the coupling housing, or from the surrounding environment.

Contaminated lubricant loses its ability to reduce friction and protect against wear, leading to accelerated damage.

OverLubrication

While insufficient lubrication is a common problem, overlubrication can also cause issues. Excess lubricant can generate excessive heat due to churning, leading to thermal degradation of the lubricant and potential damage to the coupling. Overlubrication can also cause leakage, which can attract contaminants and create a safety hazard.

Degradation of Lubricant

Lubricants degrade over time due to factors such as oxidation, thermal breakdown, and contamination. Degraded lubricant loses its effectiveness, resulting in increased friction, wear, and corrosion. Regular monitoring and replacement of the lubricant are essential to prevent this issue.

Monitoring and Maintenance of Coupling Lubrication

Effective monitoring and maintenance practices are essential to ensure the longevity and reliability of couplings. These practices involve regular inspection, analysis, and replacement of the lubricant.

Visual Inspection

Regular visual inspection of the coupling and lubricant can help identify potential issues before they lead to failure. Signs of insufficient lubrication, contamination, or leakage should be addressed immediately.

For greaselubricated couplings, the condition of the grease can be assessed by its color and consistency. For oillubricated couplings, the oil level and clarity should be checked.

Lubricant Analysis

Lubricant analysis is a valuable tool for monitoring the condition of the lubricant and the coupling. This involves testing samples of the lubricant for properties such as viscosity, acidity, and contamination levels.

Changes in these properties can indicate issues such as degradation, contamination, or excessive wear. Lubricant analysis can also help determine the optimal relubrication intervals and identify the need for corrective action.

Temperature Monitoring

Excessive heat generation is a common sign of lubrication issues in couplings. Monitoring the temperature of the coupling during operation can help identify problems such as insufficient lubrication, overlubrication, or misalignment.

Infrared thermography is a noninvasive method for measuring the temperature of couplings and identifying hotspots.

Vibration Analysis

Vibration analysis is another useful technique for monitoring the condition of couplings. Changes in vibration patterns can indicate issues such as misalignment, imbalance, or wear.

These issues are often related to lubrication problems and can be addressed by adjusting the lubrication practices.

Best Practices for Coupling Lubrication

To achieve optimal performance and extend the lifespan of couplings, adhering to proper lubrication practices is essential.

This involves selecting the correct type and quantity of lubricant as recommended by the manufacturer, ensuring the lubricant is clean and uncontaminated during application, and maintaining consistent relubrication intervals while using the same type of lubricant.

Regular inspection and monitoring of both the coupling and the lubricant's condition are also critical, along with promptly addressing any identified issues to prevent further damage.

By adhering to these best practices, operators can minimize the risk of coupling failure and maximize the efficiency and reliability of their mechanical systems.

Ensuring Coupling Performance Through Effective Lubrication Practices

Coupling lubrication is a critical aspect of mechanical maintenance that directly impacts the performance, reliability, and lifespan of couplings.

From selecting the right lubricant to applying it correctly and monitoring its condition, every step plays a vital role in ensuring the smooth operation of couplings.

By understanding the principles of coupling lubrication and implementing effective maintenance practices, operators can prevent common failure modes, reduce downtime, and extend the life of their equipment.

Proper lubrication is not just a maintenance task—it is an investment in the longterm success of mechanical systems.