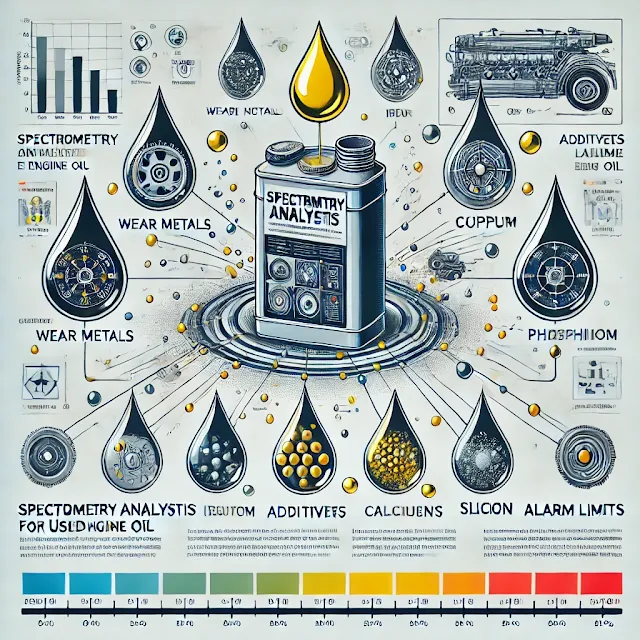

Decoding Engine Wear: The Essential Role of Spectrometry in Used Oil Analysis

Spectrometry analysis is an indispensable tool in engine maintenance, providing detailed insights into the condition of engine oils.

Through the detection and quantification of various metals, spectrometry allows for early identification of engine wear, contamination, and additive depletion.

This article explores the application of spectrometry, specifically Inductively Coupled Plasma (ICP) and Rotating Disc Electrode (RDE) techniques, in analyzing used engine oils.

Each metal detectable by these methods is categorized as a contaminant, additive, or wear metal, with an exploration of their origins, significance, and acceptable, cautionary, and alarm limits.

Spectrometry Techniques in Engine Oil Analysis

Inductively Coupled Plasma (ICP) Spectrometry

ICP spectrometry is a precise analytical technique that detects and quantifies trace elements in used engine oils.

By ionizing the sample in a plasma torch and measuring the emitted light at specific wavelengths, ICP can accurately identify and quantify multiple elements simultaneously.

This technique is highly sensitive, making it suitable for detecting elements even at trace levels.

However, it requires careful sample preparation, including dilution, which can introduce potential errors if not performed accurately.

Rotating Disc Electrode (RDE) Spectrometry

RDE spectrometry, while less sensitive than ICP, offers a simpler and faster approach to detecting metals in used engine oils.

This method involves applying high voltage across a rotating disc electrode submerged in the oil sample, vaporizing metal particles for detection based on their spectral emissions.

RDE is particularly effective in detecting larger wear particles that might be missed by ICP.

It does not require sample dilution, reducing the risk of errors, but is limited in the number of elements it can detect and is less effective at identifying trace levels of metals.

Metals Detected in Used Engine Oils

In used engine oil, metals detected through spectrometry analysis fall into three categories: contaminants, additives, and wear metals.

Each of these categories is detailed below, including the possible origins of the metals, their significance in engine health, and the acceptable, cautionary, and alarm limits for their presence in the oil.

Contaminants

Contaminants in engine oil are unwanted substances introduced from external sources or internal engine processes.

Their presence can signal poor maintenance, environmental factors, or mechanical problems within the engine.

Silicon (Si)

Silicon is typically introduced into engine oil as a contaminant from dirt and dust, often due to a faulty air filtration system.

It can also originate from silicone-based sealants used in engine assembly or maintenance.

High silicon levels suggest contamination, leading to abrasive wear on engine components.

The acceptable limit for silicon in used engine oil is below 10 ppm, with levels between 10-20 ppm being cautionary. Levels exceeding 20 ppm are alarming and indicate significant contamination.

Sodium (Na)

Sodium contamination in used engine oil often results from coolant leaks, particularly from sodium-based antifreeze.

It can also be introduced by road salt or sea spray in marine environments and may sometimes come from certain oil additives.

The presence of sodium, especially when combined with potassium and water, is a strong indicator of coolant ingress, which can lead to severe engine damage.

Acceptable sodium levels are below 10 ppm, with caution limits between 10-30 ppm, and alarm levels above 30 ppm.

Potassium (K)

Potassium in used engine oil is usually a sign of coolant leakage, especially from potassium-based antifreeze.

Elevated potassium levels signal coolant contamination, which can cause serious engine damage if not addressed.

The acceptable potassium level in used engine oil is below 5 ppm. Levels between 5-20 ppm are within the cautionary range, and concentrations above 20 ppm should trigger an alarm, indicating a significant issue that needs prompt attention.

Boron (B)

Boron can enter engine oil as a contaminant from borate-based antifreeze or as part of certain oil additives.

High boron levels may indicate coolant contamination or the depletion of boron-based additives.

While boron enhances engine oil performance, its excessive presence due to contamination can indicate potential engine issues.

The acceptable boron level is below 5 ppm, with caution levels between 5-20 ppm. Concentrations above 20 ppm are alarming and suggest a significant coolant leak or additive depletion.

Aluminum (Al)

Aluminum can be detected in used engine oil either as a contaminant from external sources like dirt or as a wear metal from the degradation of aluminum-containing engine components such as pistons and bearings.

Elevated aluminum levels can indicate either contamination or wear, both of which can negatively impact engine health.

The acceptable aluminum concentration in used engine oil is below 5 ppm, with caution limits between 5-15 ppm. Levels above 15 ppm are considered alarming, requiring immediate diagnostic action.

Lithium (Li)

Lithium can be introduced into engine oil from lithium-based greases or certain coolant additives.

Its presence in the oil could indicate contamination from external sources such as grease migration or coolant leaks.

Acceptable lithium levels are generally below 10 ppm, with caution limits between 10-30 ppm. Levels above 30 ppm should be considered alarming, suggesting significant contamination.

Vanadium (V)

Vanadium is a contaminant that may enter engine oil from the combustion of vanadium-containing fuels, such as heavy fuel oils used in marine engines.

High vanadium levels can cause deposit formation and corrosion, leading to engine damage.

Acceptable vanadium levels are typically below 1 ppm, with caution limits between 1-5 ppm. Levels exceeding 5 ppm are alarming and require immediate attention.

Nickel (Ni)

Nickel contamination can occur from external sources such as dust or from certain alloys used in engine components.

Elevated nickel levels may indicate contamination or wear of nickel-containing parts.

The acceptable nickel concentration in used engine oil is below 1 ppm, with caution limits between 1-5 ppm. Levels above 5 ppm are considered alarming and warrant investigation.

Tin (Sn)

Tin can be introduced into engine oil as a contaminant or as a wear metal. As a contaminant, it may come from external sources or the degradation of tin-containing solders or alloys.

Elevated tin levels suggest contamination or wear of tin-based components.

The acceptable tin concentration is below 1 ppm, with caution limits between 1-5 ppm. Levels above 5 ppm should trigger an alarm, indicating potential issues with engine components.

Cadmium (Cd)

Cadmium is a toxic metal that can enter engine oil through environmental contamination or from certain engine components, such as bearings or coatings.

High cadmium levels are hazardous and can indicate serious contamination.

The acceptable cadmium concentration in used engine oil is below 0.1 ppm, with caution limits between 0.1-1 ppm. Levels exceeding 1 ppm are alarming and require immediate investigation.

Chromium (Cr)

Chromium may enter engine oil from the wear of chromium-plated components or contamination from external sources.

It is often found in engines using chromium-based coatings or in areas with high industrial activity.

The acceptable chromium concentration in used engine oil is below 1 ppm, with caution limits between 1-5 ppm. Levels above 5 ppm are alarming, indicating excessive wear or contamination.

Additives

Additives in engine oil are essential for enhancing performance and protecting engine components.

Metals detected in this category are typically part of the oil formulation and should remain within specific ranges to ensure optimal oil performance.

Calcium (Ca)

Calcium is primarily used as a detergent and dispersant additive in engine oils, neutralizing acidic combustion byproducts and keeping the engine clean.

Monitoring calcium levels helps assess the oil's additive package and ensure continued engine protection.

The acceptable range for calcium in used engine oil is 1000-3000 ppm, with levels between 3000-4000 ppm indicating potential issues with oil mixing or additive depletion.

Concentrations exceeding 4000 ppm warrant immediate investigation.

Magnesium (Mg)

Magnesium, like calcium, serves as a detergent and dispersant additive in engine oils.

It plays a crucial role in maintaining engine cleanliness and neutralizing harmful acids.

Regular monitoring of magnesium levels helps evaluate the condition of the oil's additive system.

The acceptable magnesium range in used engine oil is 500-1500 ppm, with caution levels between 1500-2000 ppm.

Levels above 2000 ppm may suggest oil formulation or additive package issues that need further investigation.

Zinc (Zn)

Zinc is commonly found in engine oils as part of the zinc dialkyldithiophosphate (ZDDP) additive, which provides critical anti-wear protection.

Monitoring zinc levels ensures the oil's anti-wear properties are maintained, preventing excessive engine wear.

The acceptable zinc concentration in used engine oil is 800-1200 ppm. Levels between 1200-1500 ppm are cautionary, while concentrations above 1500 ppm may indicate potential issues with oil mixing or additive levels that could harm the engine.

Phosphorus (P)

Phosphorus, a component of ZDDP, contributes to the anti-wear and antioxidant properties of engine oils.

Its presence in used oil indicates the effectiveness of these protective additives.

Proper monitoring of phosphorus levels helps maintain engine integrity by ensuring sufficient anti-wear protection.

The acceptable phosphorus range is 600-1000 ppm, with caution levels between 1000-1200 ppm.

Levels above 1200 ppm could indicate formulation issues or excessive additive presence that might negatively affect engine components.

Molybdenum (Mo)

Molybdenum is used in certain high-performance engine oils as an anti-wear and friction modifier additive.

Its presence in used oil reflects the condition of these specialized additives, which help reduce engine friction and wear.

Monitoring molybdenum levels is crucial for maintaining engine performance, especially in high-stress conditions.

The acceptable molybdenum range is 50-300 ppm, with levels between 300-500 ppm warranting caution. Concentrations above 500 ppm may indicate over-additivization or issues with the oil formulation that need attention.

Barium (Ba)

Barium is used as a detergent additive in some engine oils, although it is less common than calcium or magnesium.

Its presence in used oil indicates the effectiveness of the cleaning agents within the oil.

The acceptable barium concentration in used engine oil is 0-10 ppm, with caution levels between 10-30 ppm.

Levels above 30 ppm suggest potential issues with the oil's formulation or contamination.

Titanium (Ti)

Titanium is occasionally used as an anti-wear or antioxidant additive in some high-performance engine oils.

Its presence in used oil reflects the condition of these specialized additives.

The acceptable titanium concentration in used engine oil is typically below 10 ppm, with caution limits between 10-30 ppm.

Levels above 30 ppm may indicate issues with the oil formulation or over-additivization.

Antimony (Sb)

Antimony is sometimes used as an anti-wear additive in engine oils.

Monitoring its levels helps assess the condition of the anti-wear additives.

The acceptable antimony concentration in used engine oil is below 10 ppm, with caution limits between 10-20 ppm.

Levels exceeding 20 ppm are alarming and may suggest over-additivization or oil formulation issues.

Sulfur (S)

Sulfur is a key component in many oil additives, including detergents and anti-wear agents like ZDDP.

High sulfur levels are expected in oils with these additives, but excessively high levels may indicate contamination from fuel or other sources.

Acceptable sulfur levels vary widely depending on the oil formulation but typically range from 3000-8000 ppm. Levels exceeding this range may warrant investigation.

Wear Metals

Wear metals are generated from the gradual wear and tear of engine components during operation.

Their detection in used engine oil is critical for identifying potential mechanical issues before they lead to significant engine damage.

Iron (Fe)

Iron is a prevalent wear metal found in used engine oil, typically originating from the wear of steel components such as cylinder liners, gears, camshafts, and bearings.

High iron levels indicate excessive wear of these ferrous components, often due to poor lubrication, contamination, or mechanical issues.

Monitoring iron levels is essential for early detection of engine wear to prevent severe damage.

The acceptable iron concentration in used engine oil is below 20 ppm, with caution limits between 20-100 ppm.

Levels exceeding 100 ppm are alarming and require immediate diagnostic action to prevent engine failure.

Copper (Cu)

Copper detected in used engine oil usually comes from the wear of bushings, bearings, and other copper or brass components within the engine.

Elevated copper levels suggest wear of these components, possibly due to oil degradation, contamination, or improper lubrication.

Monitoring copper levels is vital for diagnosing potential bearing wear and preventing engine damage.

The acceptable copper concentration in used engine oil is below 10 ppm, with caution limits between 10-50 ppm.

Concentrations above 50 ppm are alarming and indicate significant wear or other issues that need prompt attention.

Lead (Pb)

Lead is primarily associated with the wear of lead-based bearings in engines.

Its presence in used oil signals potential bearing wear, which can lead to serious engine damage if not addressed.

Monitoring lead levels helps detect early signs of bearing wear, allowing for timely maintenance and repairs.

The acceptable lead concentration in used engine oil is below 5 ppm, with caution limits between 5-20 ppm.

Levels exceeding 20 ppm are alarming and necessitate immediate investigation to prevent further damage.

Silver (Ag)

Silver can be detected in used engine oil as a wear metal, typically from silver-coated bearings or electrical contacts.

Elevated silver levels indicate wear of these components, possibly due to contamination or inadequate lubrication.

The acceptable silver concentration in used engine oil is below 0.1 ppm, with caution limits between 0.1-1 ppm.

Levels above 1 ppm are alarming and indicate significant wear.

Cobalt (Co)

Cobalt may enter engine oil as a wear metal from components such as valve seats or certain alloys used in high-stress areas.

Elevated cobalt levels suggest wear of these components, which could be due to excessive stress or poor lubrication.

The acceptable cobalt concentration in used engine oil is below 1 ppm, with caution limits between 1-5 ppm. Levels above 5 ppm are alarming and require attention.

Manganese (Mn)

Manganese is found in steel alloys used in various engine components. It can appear in used engine oil as a wear metal when these parts experience wear.

Elevated manganese levels indicate wear of steel components, often due to high operating loads or contamination.

The acceptable manganese concentration in used engine oil is below 5 ppm, with caution limits between 5-10 ppm. Levels above 10 ppm are considered alarming.

Conclusion

Spectrometry analysis of used engine oils, utilizing techniques like ICP and RDE, provides critical insights into engine condition by detecting a wide range of metals.

These metals, categorized as contaminants, additives, or wear metals, each offer valuable information about engine health, potential contamination, and the effectiveness of oil additives.

By understanding the origins, acceptable limits, cautionary thresholds, and alarm levels for each metal, maintenance personnel can make informed decisions to ensure optimal engine performance and longevity.

Regular monitoring and analysis are essential in preventing minor issues from escalating into major engine failures, thus safeguarding the operation and reliability of the engine.